Bearings are a bigger part of our lives than you probably realise, with almost every rotating piece of machinery relying on them to avoid seizing and to enable smooth running. If you have owned a trailer for more than a season or two you will have most likely serviced your trailer bearings yourself, or had someone service them for you… and if you haven’t, well, you’ve come to the right place because today we are covering some of the main ways you should be taking care of your trailer bearings, so they can take care of you!

What Are Bearings?

Bearings are quite simply a piece of machinery that assist with rotation. They support shafts and allow for smooth and free rotation without the build up of excessive heat, or the wearing of components. They are a very simple concept, however without them the world would be a very different place.

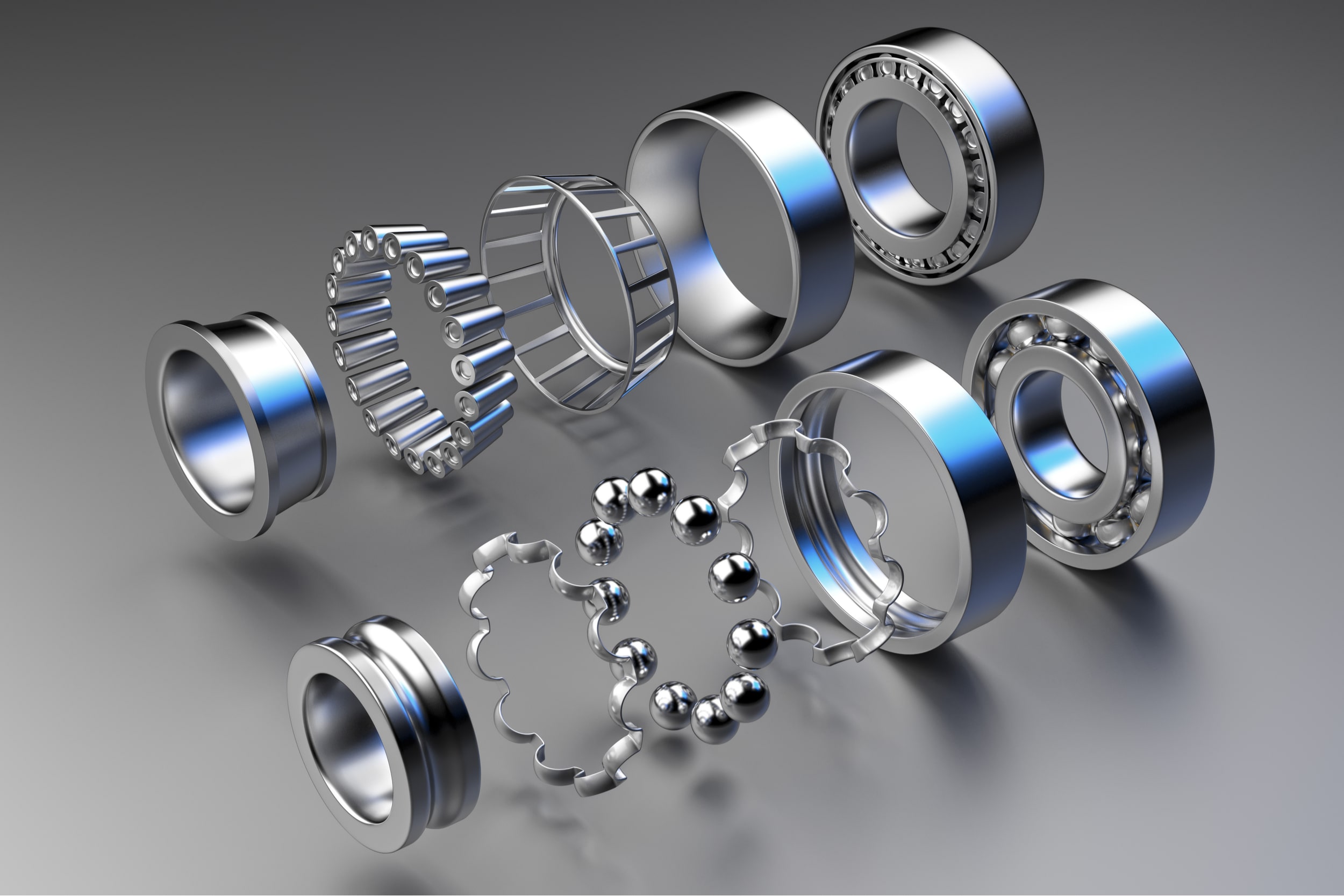

Bearings consist of four main parts, these are the inner and outer ring, the raceway, and the cage. The inner and outer rings are both typically formed from high-purity chrome alloy steel due to their long service life and high load rating. The raceway is where ball bearings or roller bearings (rolling elements) rotate. And finally, the cage is used to keep the rolling elements in place and guiding them while the bearing is rotating.

In terms of trailers, the most common (and most important) place you will find bearings is within the wheel assembly. These bearings will be taking the load of your trailer and ensuring there is a low level of friction when your trailer wheels are turning.

What Happens If Bearings Fail

Bearing issues are never fun to deal with, but thankfully these hard-wearing parts usually won’t give out on you straight away – so you should at least have some time to fix them before things get too serious. However, left untreated, a worn bearing can lead to some fairly substantial damage to your trailer, some of which may even be risking an accident. The most common parts to wear in a bearing component are the ball bearings or rollers which rotate within the raceway.

Bearings are built to an extremely high degree of accuracy, this is to make them as long lasting, quiet, and as efficient as possible. However, if the bearings begin to wear this ultra-accuracy is disrupted. As wearing worsens, the rolling elements become loose within the raceway which will lead to various symptoms, including:

- Squealing or Growling – This is a classic symptom of worn bearings, a constant but periodic squeaking sound which becomes worse as speed increases. It may also worsen when turning corners due to the extra loading on your trailer wheel bearings.

- Shaking or Vibrating – When a bearing becomes worn it becomes looser, this therefore means that when the bearing is rotated it may also have a tendency to move horizontally or laterally. In a wheel bearing this causes vibration when the trailer is being towed.

- Wheel Movement – The best way to confirm you have a worn wheel bearing is to check for movement of the wheel. To do this you must elevate the wheel, then while standing facing the side of the wheel, hold the wheel at two opposite ends and apply pressure to shake the wheel. If you feel the wheel has movement then it is most likely that your wheel bearing has been worn and should be replaced.

Replacing Bearings

If you suspect you have a worn bearing it is important to get it replaced as soon as possible. Even though bearings are tough and will take a while to complete fail on you, a failure can easily cause the wheel to completely seize.

Replacing a bearing can sometimes be a tricky job so don’t get disheartened if you feel like leaving it for a professional to do. But if you feel like giving it a go yourself here is some of our best tips to help you:

- Keeping Clean – Bearings can be quite messy due to the high amounts of grease in them to keep them lubricated. it is a good idea to have plenty of rags on hand to wipe up and mess that is made.

- Take Your Time – Due to the fine engineering that goes into wheel bearings they can sometimes be very tight. In order to instal them in the best possible condition, try and take your time to avoid damaging the new bearings of the surrounding machinery.

- Ensure the Correct Tightening – It can be difficult to correctly tighten nuts around the wheel bearings and hub, you need to ensure nuts are tightened to manufacturer specified torques to ensure the correct running of the wheel gear.

- Consider Changing the Wheel Hub – When replacing a wheel bearing you are replacing a lot of the equipment inside the wheel hub. You might find the hub itself is in a condition which could be replaced, so you should consider whether this is necessary as it could save time and effort in the long run.

Servicing Bearings

Bearings should ideally be serviced once a season, this is especially important on salt water boat trailers as corrosion can become an issue. When you are servicing your trailer bearings you should try to remove as much old grease as possible. After the bearing is clean you can inspect the condition, it is in and check for any wear.

Once satisfied the bearing is in a good useable condition it can be re-greased and replaced. When doing this you should ensure the bearing is sufficiently coated with grease, and any seals are replaced correctly to stop water ingress. Once the bearing is serviced and your wheel is replaced you are ready to go! Spring makes a great time for servicing your trailers bearings, so your trailer is ready for the season ahead.